Production Facilities

Download as in PDF Format

Taj Pharma Ltd.

Taj Pharma Ltd. (TPL) is a group venture of Taj Pharma group.

Taj Pharma Limited is our latest group venture completely dedicated to the development of innovative parenteral drug delivery systems. Established in 2009, TPL is a one-of-its-kind project with modern and state-of-the-art manufacturing facilities. TPL excels in:

1. Manufacturing empty glass pre-fillable syringes

2. Formulating glass as well as plastic pre-filled syringes

With a production capacity of 1,50,000 syringes per day, TPL is all set to be a global leader in its field of specialization, i.e., formulation and manufacture of exclusive pre filled syringes that meet all quality standards.

At TPL, we adhere to strict norms and certifications. The manufacturing facility complies with the all international regulations of US FDA, MHRA, and WHO GENEVA, etc.

With a vision to conquer new horizons of excellence, TPL’s strength lies in its use of top quality equipment and its experienced professionals. The entire manufacturing process is automated to guarantee zero contamination. From the loading of glass tubes to obtaining the final formulated syringe, there is absolutely no human intervention at any level.

At TPL, we believe in delivering the best, and nothing but the best! We make use of world class lab equipment, superior processing machines, cleanrooms, air handling systems and the best laboratory practices. With aid of our in house R & D facility, we select the best raw materials and components for the syringes to ensure quality par excellence.

If you are looking for an integrated solution to your entire parenteral drug delivery needs, your search ends at TPL.

Production Facilities

TPL has earned national as well as international acclaim for its remarkable production facilities. Here is why:

• WHO-GMP Certificate acquired.

• One of the few facilities in the country with capabilities for manufacturing and formulating pre-filled syringes.

• Comprehensive and diverse formulation sections: General, Beta lactum, Hormones, Oncoloy, etc.

• Computerized and automated process; no human touch at any level.

• Dedicated line for general products with large market stakes.

• Compliance with all international regulatory bodies: MHRA, US FDA, WHO GENEVA, etc.

• Continuous online monitoring and inspection at every step.

• Installation of 17 pre-filled syringe filling lines that function with negligible error.

• Capabilities for filling both glass and plastic syringes.

Empty Glass Prefilled Syringes

We manufacture premium quality glass pre-filled syringes which satisfy all customer requirements in toto. Their flexible design features allow optimal and easy incorporation of individual components. They are also technically compliant with all international standards in the pharmaceutical and medical device industry.

Our range comprises of:

• Sizes from 0.5 to 5ml

• Staked needle and Luer Lock syringes

• Pharmaceutical rubber formulations with variants

• All relevant interior tampering options

• Printing options

• Customized delivery forms

We can supply glass pre-fillable syringes both as bulk products and as ready for filling format: washed, siliconized, pre-assembled and sterilized in compliance with all international regulations. We have a patented trademark for our glass syringe systems and components.

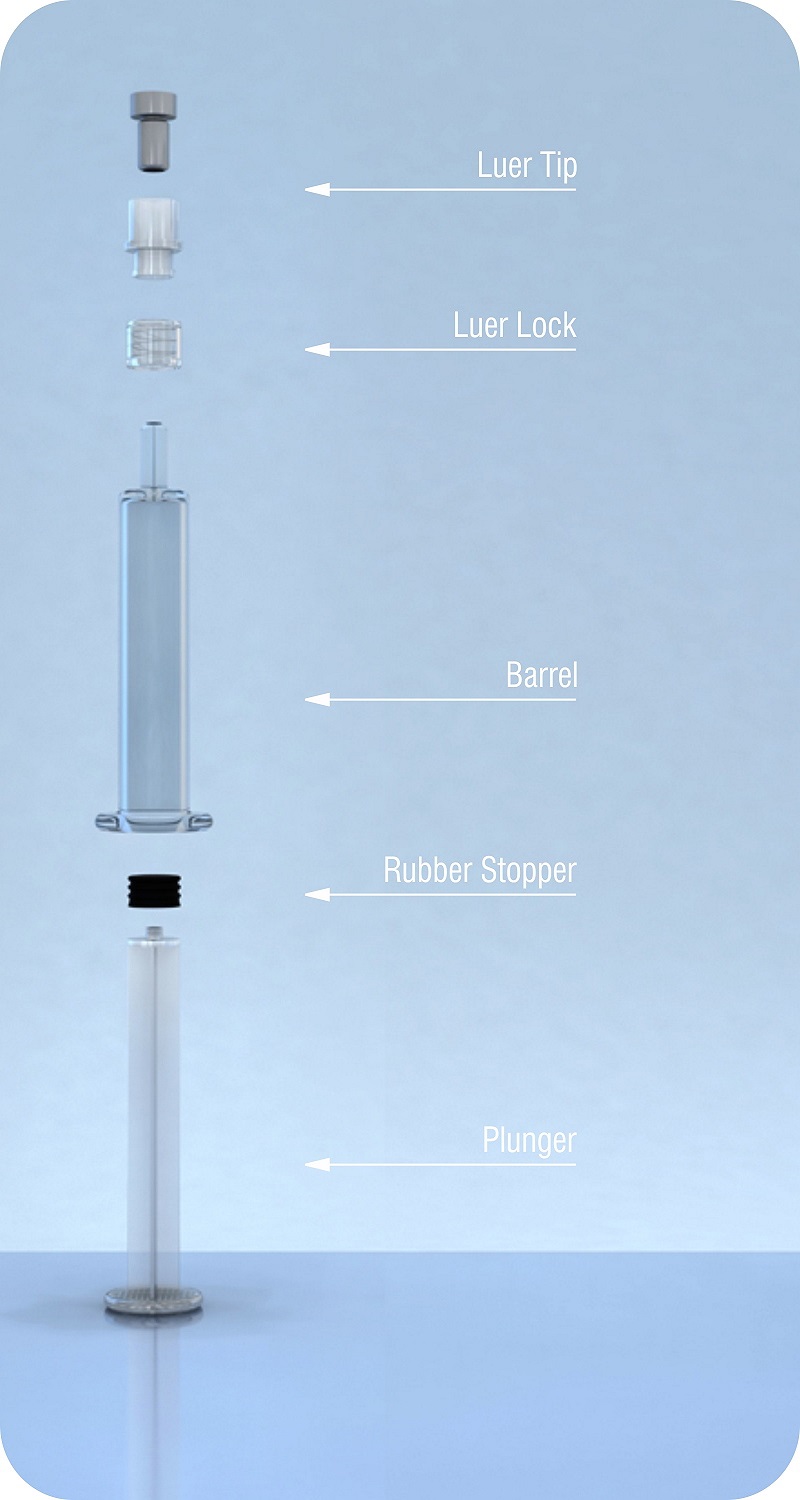

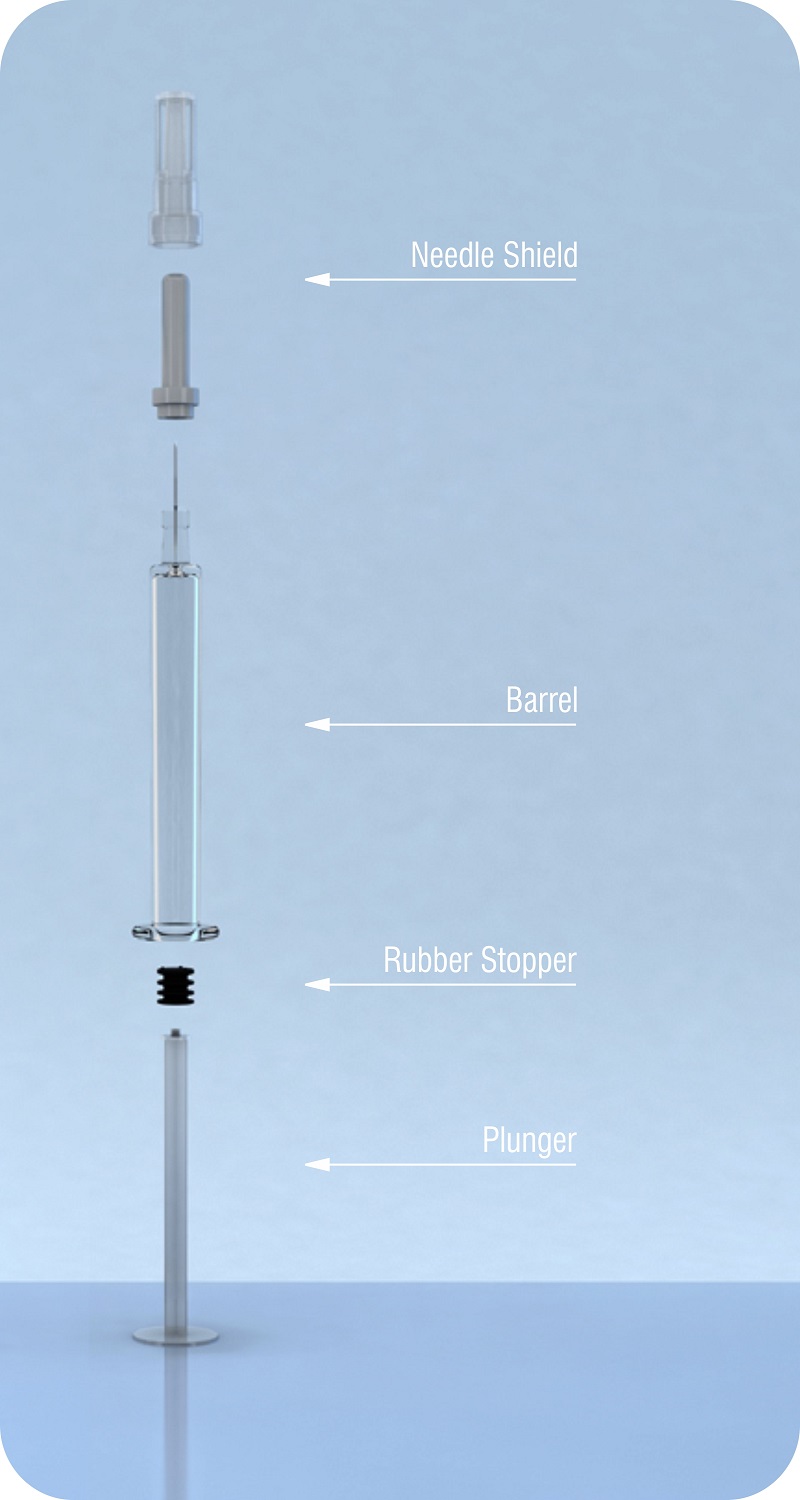

At TPL, we are focused on application safety at every stage. Needle shields with thermoplastic elastomers protect the needle point from deformation before the injection. These shields also ensure the essential sharpness of the needle. They reduce the risk of needle-staked injuries to a great deal. Tamper-evident Luer lock closure with a guided twist-off action is a salient feature of our product. Our empty glass pre-filled syringes are manufactured in a completely sterile and protected environment in an automated process with no human touch at any stage. They are compatible with all existing filling machines.

Luer Lock Syringes

Rose-Fill LL Syringes(Glass Barrels with Luer Lock)

Sizes: 1ml, 2.25ml, 5ml (Customize Sizes are available on request)

| Sr. No | Products | Id | Od | Length | Nest Packing of barrels |

| 1. | Rose-Fill 1ml LL | 8.65 | 10.85 | 46.7 | 100 |

| 2. | Rose-Fill 2.25 ml LL | 8.65 | 10.85 | 64.5 | 100 |

| 3. | Rose-Fill 5ml LL | 11.85 | 14.45 | 77.7 | 64 |

| (*all measurements in mm) | |||||

Features:

Glass barrel made of neutral glass clear, type I (as per EP/USP/JP).

Process step: Forming, Annealing, Washing/ Siliconization , DHS/ Silicon Curing, Assembling, Packaging.

ETO sterilization (Rubber components are Gamma Sterilized).

Suitable for standard filling and packaging equipment.

Printing option are available.

Round fling.

Clean Room Technology.

Accessories for Glass with Luer Lock

Luer Lock

Luer Tip

Stacked Needle Syringes

Rose-Fill Stacked Needle Syringes (Glass Barrels with Stacked Needle)

Sizes: 0.5ml & 1ml (Customize Sizes are available on request)

| Sr. No | Products | Id | Od | Length | Nest Packing of barrels |

| 1. | Rose-Fill 0.5 ml Stacked-Needle | 4.65 | 6.85 | 57.50 | 100 |

| 2. | Rose-Fill 1ml Stacked-Needle | 6.35 | 8.15 | 64 | 100 |

| (*all measurements in mm) | |||||

Features:

Glass barrel made of neural glass clear, type I (as per EP/USP/JP).

Process steps: Forming, Annealing, Washing/ Siliconization , DHS/ Silicon Curing, Assembling, Packaging.

ETO sterilization (Rubber components are Gamma Sterilized).

Suitable for standard filling and packaging equipment.

Printing option are available.

Option in Cranula sizes.

Accessories for Glass Barrels with Stacked-Needle

Assembled needle-shield

Our Branded Formulations

TPL is poised to redefine parental drug administration systems in terms of safety, stability and convenience. For this purpose, all our products are available in prefilled syringe form. We have also succeeded in overcoming the challenge of biocompatibility with the syringes of glass and plastic owing to our accomplished R & D team.

We highly recommend the use of our pre-filled syringes, the future of parental drug delivery and medications. Our syringes offer immense benefits over the conventional forms of injectable. To enlist a few:

The benefits are as follows

No chance of contamination from hand or from hospital atmosphere.

Saving valuable time in critical care management since the primary container of medication is the syringe itself.

Easy to administer.

Accurate dosage.

Eliminates human errors of wrong choice of medication in an unmarked syringe that frequently occur during an emergency.

Minimal chance of needle injury to the healthcare staff.

Minimizing medical wastage to a great deal by rendering vials and ampoules unnecessary and hence their production, avoidable.

Currently in the domestic market, we offer parental therapeutic solutions in the following product segments:

Cardiac critical care.

Anesthesia.

Gynecology.

General.

Cardiac Critical care

Anticoagulants, Catecholamine, Parental anti-anginal, Anti arithmetic agents, Sympathomimetic

Contract Manufacturing

TPL offers the attractive option of Contract manufacturing for your products! Partner with RBL and extend the lifecycle of your product by moving it from ampoules and vials to Roselabs’ Prefilled Syringes!

Life-cycle management is an integral part of the success of a brand. For the pharmaceutical industry in India, its significance is tremendous. Rather than build strong brands, many pharmaceutical companies today depend on their ability to keep the pipeline filled with new products. However, the discovery of new products has been declining, while at the same time development costs have been increasing. Patent laws do not permit reverse engineering, putting Indian companies at a disadvantage.

This is the right time for Indian companies to turn to brand life cycle management. In a hotly contested market such as India, one should opt for sophisticated and advanced drug delivery systems to set themselves apart from the competition. And therefore, for small volume parentals, prefilled syringes become a very attractive option.

End-user-friendly systems such as Roselabs prefilled syringe, cartridge and pen system turn into unique selling propositions for your product, enhancing its attractiveness and its chances of extending the life-cycle.

Roselabs Pre-filled and Pre-fillable Syringes help in:

Differentiation from competition – this will raise your brand to new heights.

Premium pricing possibilities – Economic advantages translate into better profits.

More attractive for end users- Giving your product a new edge.

Will add significant value to the treatment of a medical condition.

We believe in a strong and perpetual partnership with you…

Commercial benefits when you partner with Roselabs:

oselabs Prefilled Syringes offer tremendous savings!

Vial washing, de-pyrogenation, and vial-component preparation equipment are not required because the syringes come pre-sterilized and ready for use.

Enhanced efficiency can be achieved With prefilled syringes, overfilling is less than 2% as opposed to ampoules and vials where it may be over 18%.

Shift from conventional forms of drug delivery to the new Pre-filled technology today! Get your product filled at Roselabs, the one-of-its-kind facility where both manufacturing and the formulation of empty pre-filled syringes are done under one roof.